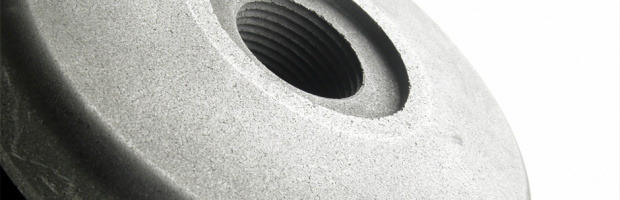

Tokai Carbon Graphite’s are manufactured to meet the demands of molten metal environments — delivering excellent thermal conductivity, and outstanding thermal shock performance. Enabling efficient heat dissipation, our Isostatic and Extruded grades are precision-machined to maintain casting integrity, reduce downtime, and extend die life. Tokai’s ultra-clean Graphite’s ensure no contamination or inclusions in your melt, making it the trusted choice for continuous casting, degassing, and other high-performance foundry processes.

Foundry

The materials and grades recommended by Tokai Carbon for these applications are shown in the table below:

| Continuous Casting | |||

| Alloy/Metal | Extruded/Moulded Graphite | Isotropic Graphite | Tokarec |

| Grey Iron | G330 & G347 | ||

| Ductile Iron | G330 & G348 | ||

| Brasses | G347, G348 & G458 | ||

| Bronzes | G330 & G348 | ||

| Copper Nickel | G348 | ||

| Nickel Silver | G348 | ||

| Precious Metals | G347 & G348 | ||

| Zinc | G347 | ||

| Aluminium Billet & Slab | G330 & G347 | ||

| Metallurgical Applications | |||

| Item | Extruded/Moulded Graphite | Isotropic Graphite | Tokarec |

| Aluminium Degassing | EE250G | ||

| Molten Metal Pumps | EE250G | ||

| Extrusion Run Out Tables | FE250 | ||

| Furnace Heating Elements | FE250 | G330 | CC28NF |

| Furnace Furniture | FE250 | G347 | CC28NF |

| Furnace Linings | |||

| Boats | FE250 | G330 | |

| Sinter Trays | FE250 | G347 | CC28NF |

| Crucibles | G140 | G348 | |

| Large Crucibles | G530 | ||