Graphite used in high temperature applications, exposed to Oxygen rich atmospheres need to be protected against oxidation. Tokai has developed as post machining process, GRAPHOX, which can reduce the rate of oxidation.

|

Anti-Oxidation treatment for graphite |

In the presence of heat and oxygen, the surface of graphite components react and break down. This process can begin at around 400°C, and is accelerated with increasing temperature and exposure time. GraphOX, a unique post machining treatment developed by Tokai Carbon UK, protects the surface of graphite from exposure to heat and oxygen. The effects of oxidation are markedly reduced which leads to much longer component life.

Case Study

Case Study

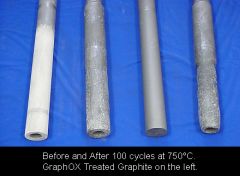

The components in the photograph on the right have been thermally cycled from ambient to 750°C and back, for 100 cycles. The untreated components show a marked degradation in the area most exposed to heat. The GraphOXtreated components are much less affected and are able to be used for many more cycles.

Typically, component life can be extended to 3 times that of an untreated component.

The unique GraphOX treatment protects well below the surface of the graphite but has no effect on the dimensions of the component