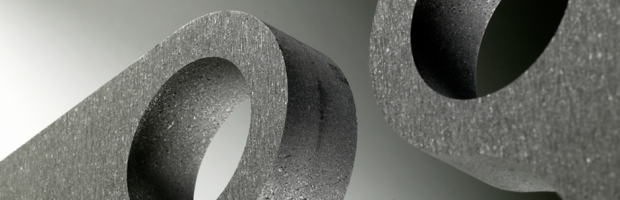

Tokai Carbon premium Graphite’s are manufactured for the toughest heat treatment environments. Withstanding temperatures up to 3000°C, our extruded and isostatic grades deliver exceptional thermal shock resistance, chemical purity, and long-lasting performance in vacuum and controlled atmospheres. Our graphite resists aggressive atmospheres and thermal shock, making it ideal for critical applications where durability and stability are essential. Whether you need components for annealing, decarburising, or high-temperature sintering, Tokai graphite offers consistent quality, reducing the risk of failure and downtime. Our materials are easily machined into complex shapes, tailored to your furnace needs.

Heat Treatment

The materials and grades recommended by Tokai Carbon for these applications are shown in the table below:

| Vacuum Furnaces | |||

| Application | Extruded/Moulded Graphite | Isotropic Graphite | Tokarec |

| Heating Elements | FE250 | G330 | CC28NF |

| Furnace Furniture | FE250 | G347 | CC28NF |

| Furnace Linings | FE250 | ||

| Boats | FE250 | G330 | |

| Sinter Trays | FE250 | G347 | CC28NF |

| Crucibles | G140 | G348 | |

| Large Crucibles | G140 | G530 | |

| Electrical Steel Production | |||

| Application | Extruded/Moulded Graphite | Isotropic Graphite | Tokarec |

| Conveyor Rolls | FE250, FE250T | G330, G330T | |

| Carbon Fibre Production | |||

| Application | Extruded/Moulded Graphite | Isotropic Graphite | Tokarec |

| Furnace Structure | CC28NF | ||

| Heating Elements | FE250 | ||